Tips & Tricks. It saves money, effort, and resources: collecting, shredding, and compressing strapping bands. The snippets or bales can ideally be processed into new straps. But what should you keep in mind? We have put together the most important points for you.

The most important aspect when sorting is the “purity" of the bands being collected. It’s hard to distinguish between PP and PET with the naked eye. However, there are a few tricks to see the difference: PP strapping bands are usually narrower and lighter. They are also more flexible and can normally be cut with standard scissors. The most common PP strapping bands are white, blue, or black—though other colors are possible. PET strapping bands are generally a bit wider and heavier, often green or black. These bands are stiffer and can often only be cut with difficulty without special tools.

Since color alone does not provide the best clue, distinguishing them can be challenging. Here, the sink-float test comes in handy! Due to the density of the plastics, the heavier PET material sinks, while PP floats on water!

It is also important that no other foreign substances such as cardboard, paper or film residues, labels, aluminum cans, screws, nuts, metal shavings, or other packaging or consumables end up in the collection. Only strap should be made from strap!

Strapping band shredder. Balling press.

Both reduction and compaction options offer their own advantages—so the decision can be made depending on the case of use. The snippets are loose and can therefore be more easily processed into recycling in the following step. The bales, on the other hand, are more manageable in transport. Whichever method suits you, one thing is certain: you will be part of a cycle full of benefits. For your company and the environment!

Collecting

made easy.Get the most out of each strap.

Keep your materials seperate!

The sink-float test helps.

Please, bands only!

Two compressing options, so many benefits!

A band shredder effortlessly cuts all common plastic straps into small pieces, whether PP or PET. The straps are manually fed and automatically drawn in. The snippets fall out of the machine at the bottom and reduce the volume up to 30-fold. The pieces are collected in Big-Bags. Here, standard Big-Bags can be used—preferably reusable ones! We are happy to provide these upon request. Pick-up is done on pallets.

A baling press can also drastically reduce the volume of the material. Particularly when a lot of waste is generated, the press may be the better choice. Here, the band is compressed into bales under pressure and transported on pallets.The right solution for everyone!

Author: vfnm

better.collect

A cycle

full of benefits!

Why “thinking in circles” is changing the world.

Every company that takes responsibility wants to save on packaging materials. This is not always easy: packaging cannot be completely ignored, since it protects the goods during shipping. Also, reduction is only possible to a certain degree: too little packaging material can have the opposite effect, leading to more transport damage and increasing resource consumption.

Reusing straps, on the other hand, is not possible on a 1:1 basis due to their material properties like band tension.

This leaves us with one remaining solution: recycling. Ideally, strapping becomes strapping again and not a recyclate used for the production of other plastic products like toys.

From linear to circular economy!

We are used to materials being disposed of and immediately replaced as soon as they are no longer needed. It is time to let go of this way of thinking!

As is true for many things, changing the perspective changes everything: if we see a used product not as waste, but as a valuable raw material, a system full of benefits emerges: our better.collect cycle!

This way, we crucially reduce resource consumption, extend the lifespan of materials, and decrease CO2 emissions!

Strong partners for big goals.

In contrast to linear economy, Circular economy means reusing materials that are in circulation already. To completely close the loop for straps, many gears must interlock. And we achieve this together with strong partners!

Packaging & Shipping.

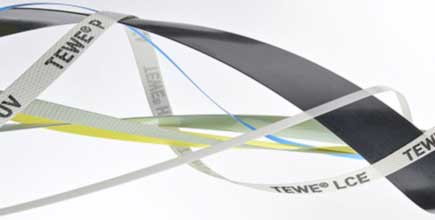

Tested in our own strapping center, our high-performance bands secure the highest quality packaging solutions. We offer the right PP or PET band for every application. But we think further – beyond the production and sale of our products! They do not end up as waste, but as a valuable raw material…

Collect & Compress.

Strapping can take up valuable storage space as individual bands. As small pieces or pressed bales, they are extremely space-saving and economical. With a band shredder or a band press, compressing is easy. The bands are collected sorted by materials (PP or PET) as bales or in Big-Bags.

Pickup.

We take care of the transport of the shredded bands, whether directly or with the help of our partner network, which is constantly being expanded. We always aim for full transport loads to keep the collection and transportation as ecological as possible!

Recycling & Reuse.

Now the material is processed and washed. Our strapping bands are perfect for recycling: after all, they can be classified as monomaterial due to their composition. PET and PP bands are 100% recyclable!

Beginning & ending of the cycle.

As a valuable raw material, the strapping band comes back to us – and the very best emerges from it: strapping band from Teufelberger!

When all the gears interlock, the circle closes – and opens up new advantages! Over and over again.

Any Question? Feel free to get in touch with us now.

Strap to Strap.

Logistics makes

all the difference!

Minimize effort, maximize benefits.

With our better.collect cycle, strapping band becomes new strapping band. This is good for the environment and minimizing effort, costs, as well as resource consumption. However, what sounds simple and requires complex logistics and perfectly cooperating partners.

The good news? We take care of exactly this logistics and the costs behind it! After all, we want to make it as easy as possible for our customers to be part of this cycle and achieve their sustainability goals.

Specifically, this means:

Our customers separate the straps by materials (PET or PP), then shred or press to compress them. It’s simple, space-saving, and resource-efficient. We offer a solution tailored to each customer and collect the straps in Big-Bags provided by us.

With our constantly expanding partner network we take care of everything else.

The collected, used strapping bands are picked up and transported, processed with the latest technology at recycling companies, and reintroduced into the cycle as raw material. The cleaner the collection, the more is returned to the cycle.

The first steps have been taken. With the continuous expansion of our partner network and perfected logistics, we can further develop our better.collect cycle with all its benefits.

For a win-win-win situation for everyone:

The collectors win, because they can be sure that the material is processed in the best possible way and they can achieve their environmental goals. We as manufacturer win by not having our straps go to waste. And of course, the environment wins – the most important beneficiary of all!

Any Question? Feel free to get in touch with us now.

Partner for tomorrow.

Closing the circle

with PreZero.

Side by side into a clean future.

Those who think anew and really want to change something for tomorrow primarily need one thing: a partner who shares these perspectives and goals. And we have found exactly such a partner in PreZero—one of Europe’s leading environmental service providers!

As a waste and recycling specialist, PreZero has been managing the strapping band waste from existing and new customers in Germany for us since 2024. Thanks to more than 120 locations, the material is quickly picked up and centrally collected. The transport from Germany to Austria occurs in regular cycles.

Together we close the strapping band cycle.

Polypropylene and PET strapping bands are collected by PreZero, handed over to the recycling partner, and processed into band granulate. A valuable raw material from which the very best emerges: new strapping band. “Strap to Strap” is the motto—a closed loop full of advantages for everyone.

The Strap to Strap solution perfectly fits PreZero’s vision of “New Thinking for a Clean Tomorrow”. The company is part of the international Schwarz Group, which pursues a common sustainability and climate strategy. The efficient circular economy ideally contributes to this.

They are a great partner with great goals, thanks to which we can offer our customers an optimal solution for the collection, disposal, and recycling of strapping bands. Thus, together, a cycle full of benefits is created: for everyone. For tomorrow.

Any Question? Feel free to get in touch with us now.